Our small precision CNC gang-tool lathes use a flat-bed structure and can be equipped with automatic feeders to support continuous, unattended machining. With functional expansion, the lathes can evolve into flexible multi-purpose platforms.

Suitable parts: pin-type components with L/D ≥ 3

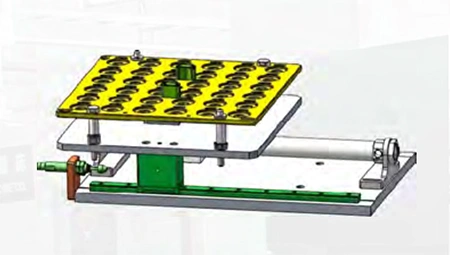

A single-axis or dual-axis sliding table sits directly behind the spindle. Raw parts are placed in the matrix tray holes and mounted onto the sliding table. The loading device transfers each part to the spindle chuck. After machining, the finished part is returned to the tray. The entire tray can then be removed and replaced as a complete unit.

Suitable parts: components requiring secondary clamping

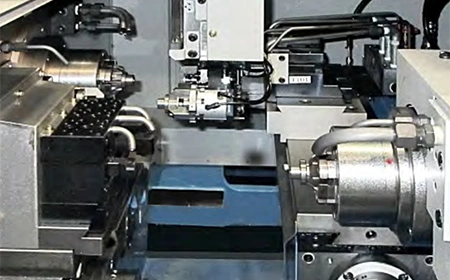

The dual-spindle layout uses either a single-slide or dual-slide structure to perform automatic part transfer inside the machine. This setup supports high-precision machining by eliminating manual repositioning and ensuring consistent accuracy.

Suitable parts: components without strict surface-appearance requirements (possible contact and friction between blanks and chute)

The vibratory feeding unit (vibrating bowl and linear feeder) is usually placed behind the lathe. Part blanks are arranged and fed in sequence, then guided through a chute or tube to the CNC gang-tool lathe. A separation mechanism isolates each blank, and the loading device (push, lift, or clamp type) transfers the blank into the spindle chuck. A conveyor belt is generally positioned at the front of the machine. After machining, the unloading device (clamp or ejector type) places the finished parts onto the belt for transfer to an external storage area.

Suitable parts: components with pure machining time ≥ 12 seconds

A two-axis or three-axis gantry robot with dual grippers is used for automatic loading and unloading. The gantry can be mounted directly on an integrated base plate or installed as a floor-standing separated structure. The system includes a dual-layer enclosure with an automatic top door. Part feeding options include step-feed conveyor lines, single-axis or dual-axis matrix-tray discharge, multi-layer matrix-tray elevators, and rotary-tray elevator systems.

Suitable parts: components requiring 1-to-2 or 1-to-3 cycle-time matching

A single robot generally services two or three machines. For two-machine setups, the robot is positioned in the center with the machines arranged opposite each other or at a right angle. For three-machine setups, the machines are arranged in a triangular pattern around the robot. Material supply options include step-feed conveyor lines, matrix-tray discharge, multi-layer matrix-tray elevators, and rotary-tray elevator systems.

Automated production line for automotive A/C compressor pistons

Automated production line for automotive A/C compressor pistons

A robot works with CNC lathes to support automatic part transfer, overhead gantry handling, and integration with gear hobbing machines, forming a complete solution for shaft and gear machining.

A robot works with CNC lathes to support automatic part transfer, overhead gantry handling, and integration with gear hobbing machines, forming a complete solution for shaft and gear machining.

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.