R&D and Design

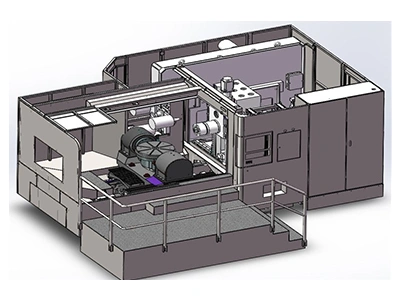

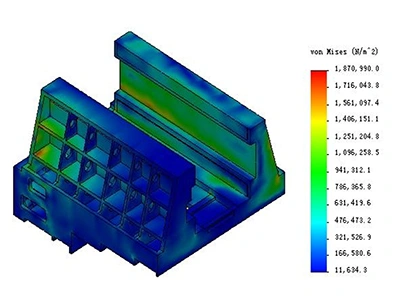

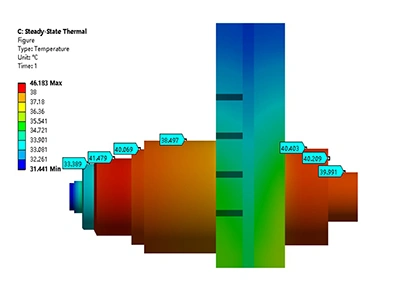

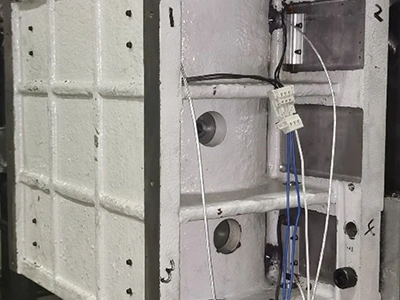

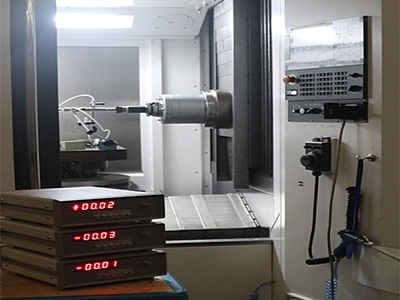

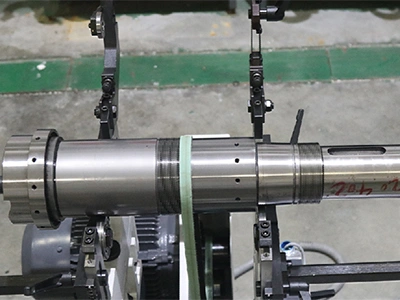

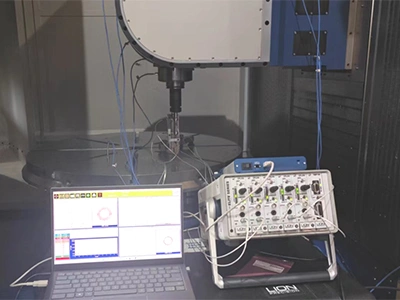

PUSH NINGJIANG Research Institute operates five specialized technical research institutes, supported by seven dedicated technical laboratories. The entire product development process is fully digitalized, covering CAD, CAE, CAM, PDM, and CAPP. We also manage an advanced engineering testing center equipped with infrared thermal imaging systems, vibration analysis instruments, and spindle dynamic testing equipment. Multiple testing platforms, such as the linear axis testing platform and spindle testing platform, enable systematic verification of new products. Every prototype must undergo performance testing and improvement trials before entering production.

The company maintains a strong technical team

- 757 Total staff

- 310+ Engineers and technicians

- 15+ Senior experts

- 75 Authorized patents, including 20 invention patents

R&D center

R&D center

Laboratory

Laboratory

Technical team

Technical team

Technical team

Technical team

Technical team

Technical team