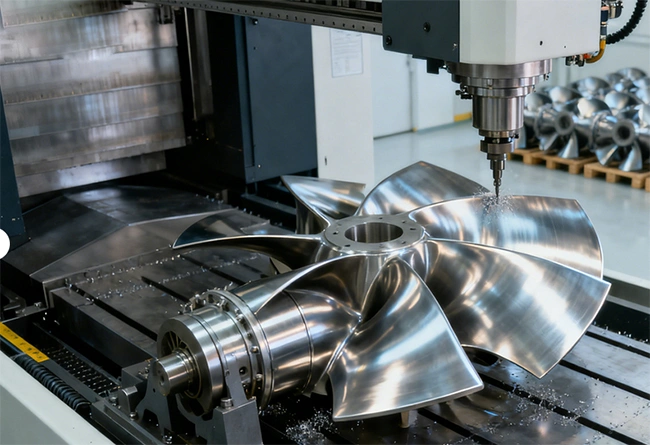

Aircraft engines are often described as the “crown jewel of modern industry,” and for good reason. Key components such as casings, blades, blisks and combustion chambers push metal machining to the limits of precision, stability and process reliability.

We have developed a dedicated portfolio of five-axis machining centers specifically for aero-engine applications to meet all the high needs. The series includes multiple configurations, such as cradle-type, 45° tilt-head and fork-type spindle head designs, to accommodate the diverse geometries and machining challenges of engine casings, blade structures and high-strength aerospace alloys.

Representative models include:

THM6380IV (cradle type), THM63100IV (cradle type), THM63120IV (cradle type), THM6380V (45° tilt-head), THMD63100V (45° tilt-head), THMD63125V (45° tilt-head), THMD63100VI (fork-type head), THMD63125VI (fork-type head).

These CNC machines deliver stable precision for complex curved surfaces, deep cavity structures, angled features and high-strength materials commonly found in aircraft engine components.

Aerospace - Engine casing

Aerospace - Engine casing

Aerospace - Combustor casing

Aerospace - Combustor casing

Aerospace - Blisk (blade disk)

Aerospace - Blisk (blade disk)

Contact us for technical details, quotations or application-specific solutions. Our team will respond shortly.