Inquiry

- Max. working diameter (mm): Ø160

- Max.working module (mm): 3

- Max. Workpiece Diameter spindle speed (r/min): 400

- Max. hob spindle speed (r/min): 2000

- Hob shifting length (Y-axis) (mm): 100

- Z-axis travel (mm): 250

- Hob head swing angle (°): ±45

- Min. tooth number (teeth): 3

- Max. hob size (diameter×length) (mm): ∅80×100

- Total power (kVA): 14

- Overall dimensions (L×W×H) (mm): 2160×3670×2580

- Machine weight (t): 6

Inquiry

- Max. working diameter (mm): ∅180

- Max.working module (mm): 4

- Max. Workpiece Diameter spindle speed (r/min): 600

- Max. hob spindle speed (r/min): 2200

- Hob shifting length (Y-axis) (mm): 150

- Z-axis travel (mm): 300

- Hob head swing angle (°): ±45

- Min. tooth number (teeth): 3

- Max. hob size (diameter×length) (mm): ∅110×160

- Total power (kVA): 30

- Overall dimensions (L×W×H) (mm): 2270×2580×2760

- Machine weight (t): 7

Inquiry

- Max. working diameter (mm): ∅200

- Max.working module (mm): 4

- Max. Workpiece Diameter spindle speed (r/min): 500

- Max. hob spindle speed (r/min): 3500

- Hob shifting length (Y-axis) (mm): 220

- Z-axis travel (mm): 350

- Hob head swing angle (°): ±45

- Min. tooth number (teeth): 3

- Max. hob size (diameter×length) (mm): ∅110×220

- Total power (kVA): 40

- Overall dimensions (L×W×H) (mm): 2700×3745×3100

- Machine weight (t): 11

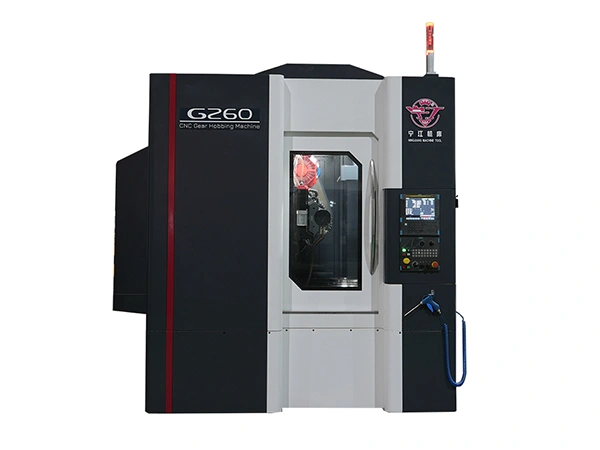

Inquiry

- Max. working diameter (mm): ∅260

- Max.working module (mm): 4

- Max. Workpiece Diameter spindle speed (r/min): 150

- Max. hob spindle speed (r/min): 1500

- Hob shifting length (Y-axis) (mm): 160

- Z-axis travel (mm): 300

- Hob head swing angle (°): ±45

- Min. tooth number (teeth):

- Max. hob size (diameter×length) (mm): ∅130×180

- Total power (kVA): 37

- Overall dimensions (L×W×H) (mm): 2420×3460×3060

- Machine weight (t): 9