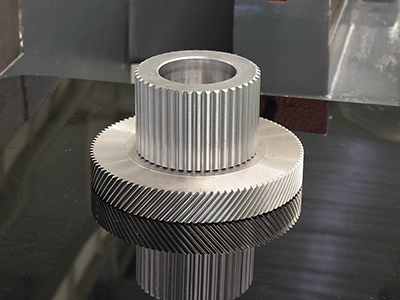

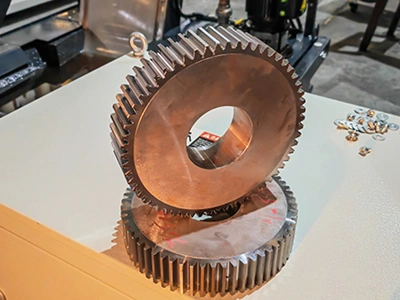

The YK7226 CNC grinding machines are designed for precise gear grinding in sectors such as instrumentation, automotive components and high-precision planetary reducers. It handles module 0.5–4 mm and workpieces up to Ø260 mm, covering the typical range required for small and medium gears. Grinding accuracy reaches GB3, which allows the machine to handle detailed finishing requirements as well as stable, efficient batch production.

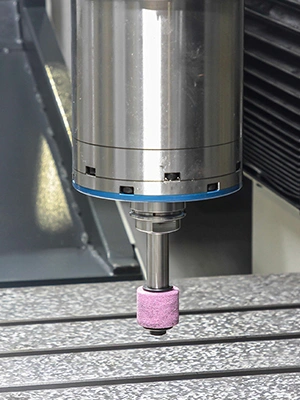

- Max. working diameter (mm): ∅100

- Working module (mm): 0.5–2

- X-axis travel (mm): 270 (100-370)

- Y-axis travel (mm): 190 (0-190)

- Z-axis travel (mm): 300 (150-450)

- Z1-axis travel (mm): 350 (475–825)

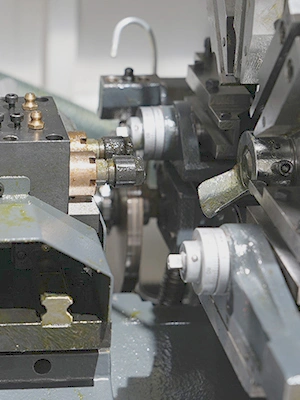

YK7210 gear grinding machines use a continuous generative grinding method that works in a motion pattern similar to hobbing. It is suitable for module 0.5–2 mm and workpieces up to Ø100 mm, making it a good choice for small gears that require both accuracy and consistent production efficiency.

- Max. working diameter (mm): ∅260

- Working module (mm): 0.5–4

- X-axis travel (mm): 245 (112.5-372.5)

- Y-axis travel (mm): 220 (0-220)

- Z-axis travel (mm): 280 (170-450)

- Z1-axis travel (mm): 315 (335–650)