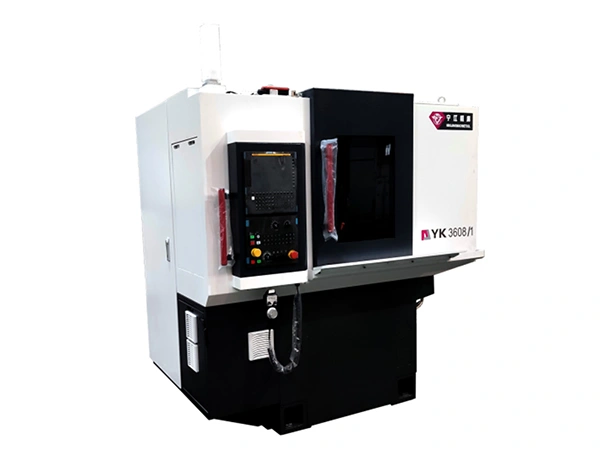

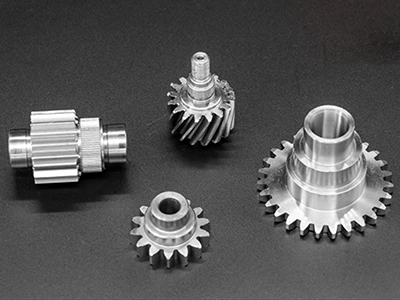

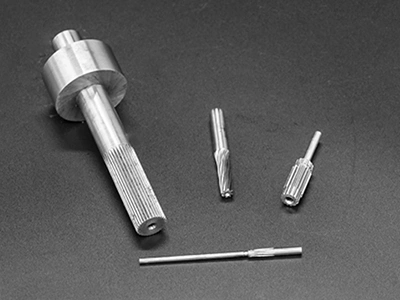

This series of CNC horizontal gear hobbing machines handles workpieces up to Ø80 mm and is suitable for machining spur gears, helical gears, worm gears, sprockets, timing-belt pulleys and splined parts.

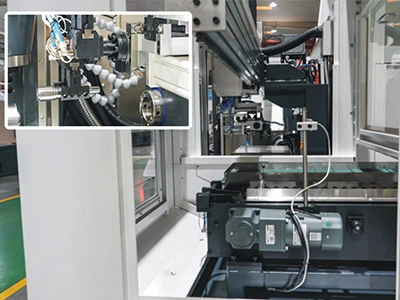

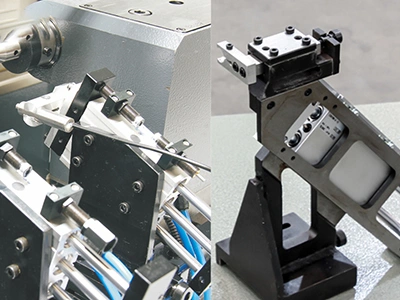

The linear axes are built with hand-scraped guideways, which provide strong rigidity and good vibration damping during cutting. The hob spindle is directly driven by a servo motor, offering steady torque transmission for small and medium gear sizes. An optional secondary tool station can be added for post-hardening finishing, allowing gears to be re-cut after heat treatment when higher accuracy is required.

Configured with the FANUC 0i-MF/H CNC system using a five-axis setup with four-axis interpolation. The horizontal layout is built for stable gear cutting. The workpiece spindle is driven by a servo motor and a precision gear-reduction assembly, allowing higher torque output for small and medium gear sizes.

Equipped with the FANUC 0i-MF CNC system with five-axis control and four-axis interpolation. The workpiece spindle uses a servo motor with a precision reduction system to increase torque output. The setup supports left-hand helix angles up to 65°, suitable for worm wheels and large-angle gears used in products like fishing reels.

The 0i-MWF Plus system works with a six-axis setup and four-axis interpolation. The workpiece spindle uses two synchronized servo motors with a precision reduction gear to boost torque. The design supports left-hand helix angles up to 65°, suitable for large-angle gears used in fishing-reel applications.

| Model | | | |

| Max. working diameter (mm) | ∅80 | ∅80 | ∅80 |

| Max.working module (mm) | 2 | 1.5 | 1.5 |

| Max. Workpiece Diameter spindle speed (r/min) | 500 | 500 | 500 |

| Max. hob spindle speed (r/min) | 2000 | 2000 | 3000 |

| Hob shifting length (Y-axis) (mm) | 60 | 60 | 60 |

| Z-axis travel (mm) | 150 | ||

| Hob head swing angle (°) | ±40 | -40– 65 | -40– 65 |

| Min. tooth number (teeth) | 3 | 3 | 3 |

| Max. hob size (diameter×length) (mm) | ∅63×60 | ∅63×60 | ∅63×60 |

| Total power (kVA) | 10 | 10 | 10 |

| Overall dimensions (L×W×H) (mm) | 1950×1285×2100 | 1950×1285×1980 | 1950×1285×1980 |

| Machine weight (t) | 3 | 3 | 3 |

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.