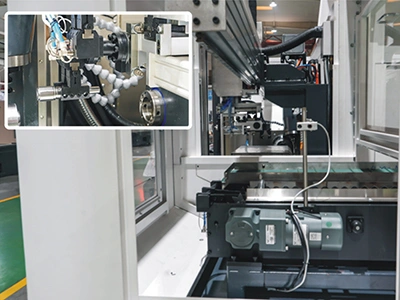

CNC horizontal gear hobbing machines in this size range are designed for workpieces up to Ø30 mm. They can machine a variety of small components used in precision devices, including spur gears, helical gears, worm gears, sprockets, timing-belt pulleys and splined parts. These gear cutting machines maintain steady mass-production accuracy at GB7, with fine cutting reaching GB6, making them suitable for efficient machining of small and micro-module gears in instrument and measurement applications.

| Model | | | |

| Number of controlled axes (pcs) | 8 | 5 | |

| Max. working diameter (mm) | ∅30 | ||

| Max.working module (mm) | 0.5 (optional: 0.8 for copper/aluminum easy-cut materials) | ||

| X-axis travel (mm) | 75 | 40 | |

| Y-axis travel (mm) | 90 | 90 | |

| Z-axis travel (mm) | 75 | 75 | |

| Z1-axis travel (mm) | 75 (servo) | 30 (pneumatic) | |

| Tooth range (teeth) | 3–999 | ||

| Hob head swing angel (°) | ±30 | ||

| Max. hob size (D x L) (mm) | ∅25×30 | ||

| Hob mandrel diameter (mm) | ∅3.5, ∅4.5, ∅5, ∅6, ∅8, ∅10 (available in long and short types) | ||

| X/Z-axis rapid speed (m/min) | 6 | ||

| Total power (kVA) | 6 | 5 | |

| Air supply | Air pressure (MPa) | 0.5–0.7 | |

| Air flow rate (L/min) | 200 | ||

| Machine dimensions (L×W×H) (mm) | 1795×1300×1899 (including operator panel space) | ||

| Machine weight (t) | 1.5 | 1 | |

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.