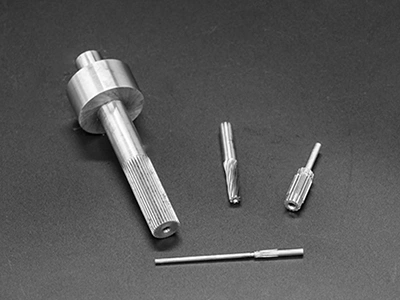

The CK1101Ⅱ CNC sliding-head automatic lathe provides the test-probe industry by offering a fully integrated machining solution that emphasizes high precision, comprehensive process capability, and advanced automation.

The system utilizes the structural benefits of a sliding-head lathe and a dedicated process design to efficiently complete nearly all turning–milling operations for probe components in one stable cycle. This approach is ideally suited to the machining characteristics of test probes, as it ensures that turning, the core process, is complemented by micro-milling and micro-drilling executed with exceptional precision.

| Challenges in Test Probe Machining | CK1101Ⅱ Solutions |

| Extremely small dimensions (diameters below 0.2 mm) | The CK1101Ⅱ uses a guide-bushing support structure positioned close to the cutting point, greatly improving bar rigidity and suppressing vibration. This enables stable machining of ultra-fine bars, including diameters as small as Ø0.1 mm. |

| Very high accuracy requirements (tolerances often within ±0.002 mm) | A high-precision feed system using linear guideways and ball screws combined with a stable spindle ensures excellent positioning and repeatability to meet micron-level tolerances. |

| Complex geometries (slots, flats, steps, micro-holes, and similar features) | Its strong compound-machining capability, with axial and radial driven tools, allows all processes such as turning, grooving, milling flats, milling slots, cross-drilling and radial tapping, to be completed in a single setup, preventing errors caused by multiple clamping operations. |

| Difficult materials (beryllium copper, palladium copper, high-elasticity alloys, etc.) | High machine rigidity supports stable cutting forces, while optimized cutting parameters can be applied for different materials. A reliable cooling system keeps the machining zone thermally stable and supports consistent cutting of hard-to-machine alloys. |

| Large production volumes requiring high consistency | Automatic bar feeding enables uninterrupted production. When connected to a bar feeder, the system supports fully automated continuous operation, ensuring consistent quality across thousands or even tens of thousands of parts. |

| High surface-finish requirements | A high-speed spindle (with optional speeds in the tens of thousands of rpm) paired with fine feed control produces superior surface quality, reducing or eliminating the need for post-processing. |

Contact us for technical details, quotations or application-specific solutions. Our team will respond shortly.