PUSH NINGJIANG has deep experience in developing customized equipment solutions for multiple industries. We provide tailored systems for automotive manufacturing, compressors, food processing, nuclear power applications, and many other production scenarios.

Strong R&D and manufacturing capability allows us to deliver more than 300 customized machines each year. This includes over 200 automotive production lines and more than 40 compressor production lines. These solutions help customers improve workflow, enhance efficiency, and achieve stable, high-quality production.

Nuclear power

Nuclear power

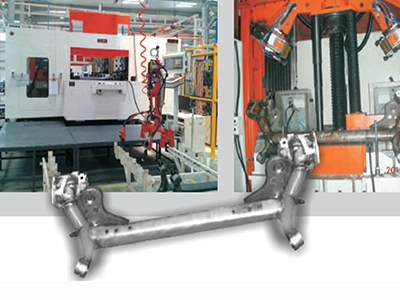

Automotive

Automotive

Energy

Energy

Food processing

Food processing

Compressor

Compressor

Medical equipment

Medical equipment

Automation systems

Automation systems

Once the order is confirmed, we follow the process and keep customers updated about the production progress and quality checks in real-time, so everything stays clear and easy to follow.

After-Sales ServiceWe provide a one-year comprehensive warranty that covers core components and labor. Our technical team responds quickly to service requests. We also offer regular equipment inspections and system upgrades to keep machines running in a stable and reliable condition.

We offer one year of free programming training for new customers. The training content is tailored to the customer’s industry and machining needs, including CNC system operation, programming techniques, and accuracy settings.

Sessions are delivered by senior engineers through a combination of theory and hands-on practice, helping customer teams build programming capability quickly and support multi-variety part production.

We offer digital catalogs across all equipment types, with details such as technical specifications, application cases, 3D models, and industry solutions. Customers can download the latest versions at any time through our website. We keep the content updated to support their decisions and future upgrades.

We’re here to help!