The CNC jig boring machine completes drilling, enlarging, boring, reaming, milling and tapping in a single setup. It is especially effective for machining precision holes in engine casings, where accuracy and repeatability are critical.

It handles difficult materials such as nickel-based superalloys, titanium alloys, stainless steel, aluminum–magnesium alloys, alloy steels and tool steels.

Typical applications include semi-finishing and finishing of high-precision hole systems in aero-engine casings, discs and rings.

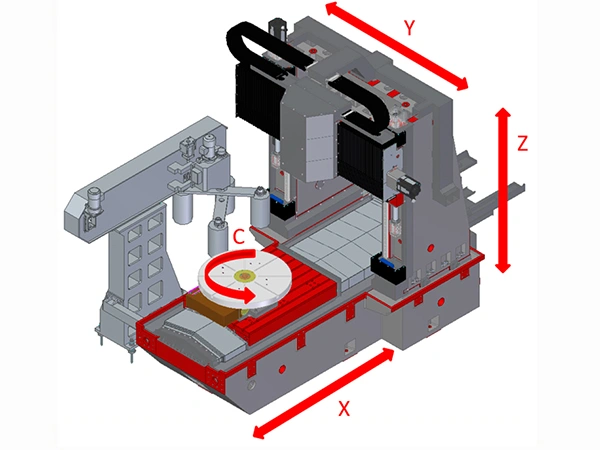

Equipped with X, Y and Z axes. Optional CNC rotary table (C-axis) or CNC cradle table (A/C-axis) is available, enabling full five-axis machining.

All servo motors, ball screw nuts and spindle bearings are cooled by a constant-temperature system to remove heat generated during high-speed operation. This improves accuracy retention over long machining cycles.

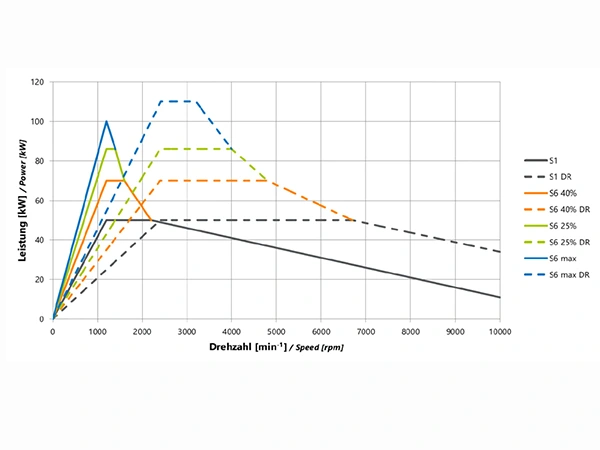

Power Curve

Power Curve

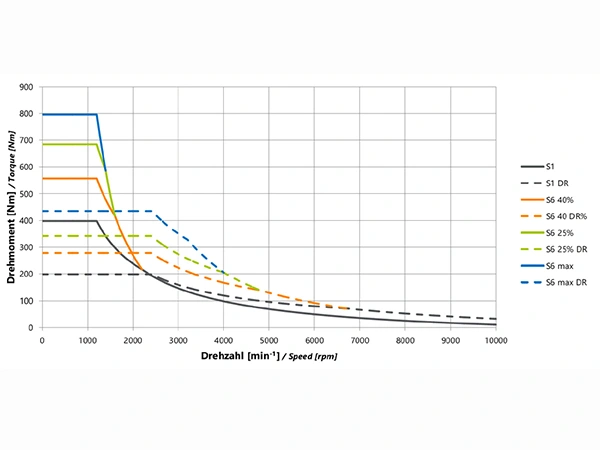

Torque Curve

Torque Curve

| Worktable | ||

| Worktable size (mm) | 1200×1600 | |

| Worktable type | T-slot | |

| T-slot size | 7-22H12 | |

| Max. worktable load capacity (kg) | 3000 | |

| Max. Workpiece Diameter height (mm) | 1000 | |

| Axes Travel | ||

| X-axis travel (mm) | 1600 | |

| Y-axis travel (mm) | 1200 | |

| Z-axis travel (mm) | 1000 | |

| C-axis rotation range (°) | n×360 | |

| Distance from table surface to spindle nose (mm) | 350–1350 | |

| Spindle | ||

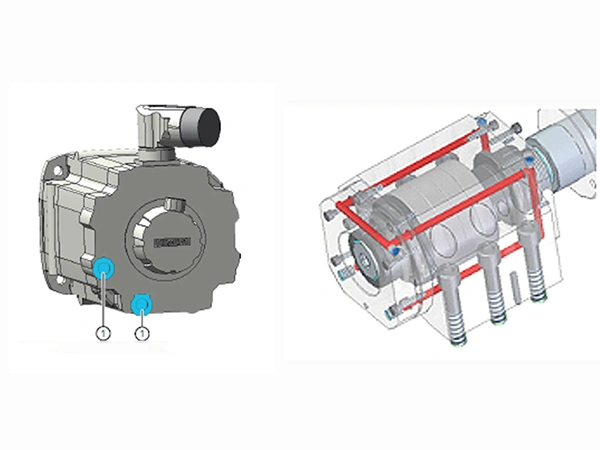

| Spindle taper | HSK-A100 | |

| Spindle speed range (r/min) | 20–10000 | |

| Speed selection | Fully programmable | |

| Spindle motor power S1/S6 (kW) | 50/70 | |

| Spindle motor torque S1/S6 (N.m) | 400/560 | |

| Tool Magazine | ||

| Number of tools | 40 | |

| Tool interface type | HSK-A100 | |

| Rated tool clamping force (kN) | 60 | |

| Max. tool diameter (mm) | Ø125 (with adjacent tools) | |

| Ø250 (without adjacent tools) | ||

| Max. tool length (mm) | 500 | |

| Max. tool weight (kg) | 25 | |

| Tool change time, tool-to-tool (s) | 4 | |

| Tool change time, cut-to-cut (s) | 10 | |

| Tool selection mode | Random bidirectional | |

| Drive & Feed | ||

| Feed speed range (X/Y/Z) (m/min) | 0–10 | |

| Rapid traverse (X/Y/Z) (m/min) | 20 | |

| Position feedback (X/Y/Z) | Linear scale | |

| Machine Accuracy (GB/T17421) | ||

| Positioning accuracy (X/Y/Z) (mm) | 0.004 | |

| Repeatability (X/Y/Z) (mm) | 0.002 | |

| Standards & Compliance | ||

| GB/T 14660.1-2023: CNC vertical jig boring machine – Part 1: Accuracy testing GB/T 17421.1-2023: Machine tool test code – Part 1: Geometric accuracy under no-load or quasi-static conditions GB/T 17421.2-2023: Machine tool test code – Part 2: Determination of positioning accuracy and repeatability of numerically controlled axes | ||

| Working Environment | ||

| Total power (kVA) | 150 | |

| Power supply | 380V±10%/50Hz±1Hz/3-phase AC | |

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.

The TK42120 is designed for high-precision hole-system machining. It is suitable for mould components, precision fixtures, aerospace parts and other workpieces that require accurate drilling, reaming, tapping and fine milling in a single setup.

The positioning accuracy of the X, Y and Z axes is 0.004 mm.

Accuracy can be ensured by: