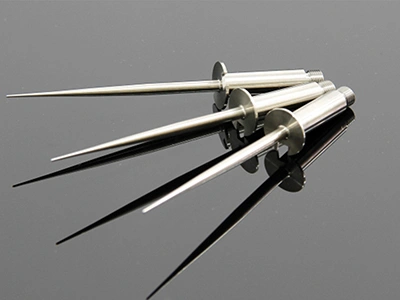

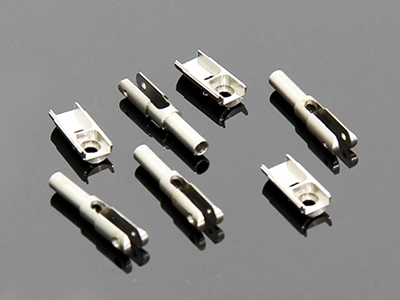

Designed for precision machining of small-diameter bar stock, this sliding-headstock automatic lathe delivers high productivity and can perform multiple processes in a single setup, including turning, reaming, drilling, and other combined operations. It is widely used for mass production in watches, precision instruments, automotive components, electronics, office equipment, medical devices, and household appliances. It is especially suited for long, slender, multi-step shaft parts that require stable dimensional accuracy.

The machine handles cylindrical turning, taper turning, spherical surfaces, contours, profiling, and cut-off. With additional attachments, it can also perform drilling, milling, and other secondary operations. The machining range covers many materials, including free-cutting steels, non-ferrous metals, and non-metallic parts, for bar diameters up to 7 mm, depending on the configuration.

Retains the high-efficiency characteristics of traditional cam-type machines, delivering stable productivity with dual-tool cutting and high machining accuracy.

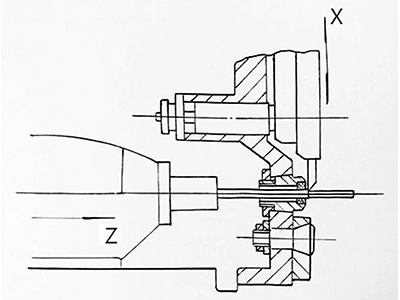

High-rigidity tool post and a symmetrical spindle design ensure consistent precision.

Well suited for machining long, slender, multi-step shaft components that require reliable dimensional control.

| Model | | | | ||

| Max. bar diameter (mm) | Ø4 | Ø7 | Ø10 | ||

| Max. Workpiece Diameter length (mm) | 50 | 66 | |||

| Max. spindle speed (r/min) | 9000 | ||||

| Max. drilling diameter | Ø4mm (copper) Ø3mm (steel) | ||||

| Spindle power (kW) | 1 | ||||

| CNC system | Dedicated CNC system | ||||

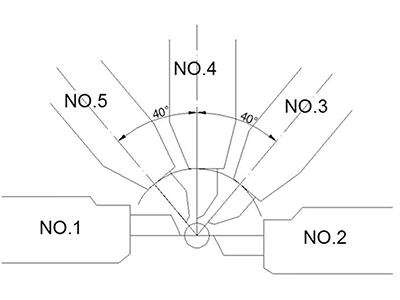

| Tool configuration | Balance turning tools ×2 (No.1, No.2) | ||||

| Vertical turning tools ×3 (No.3, No.4, No.5) | |||||

| End-face drilling holders ×2 (depending on selected attachments) | |||||

| Max. tool slide feed rate (m/min) | 16 | ||||

| Z-axis rapid traverse (m/min) | 15 | ||||

| Repeatability (mm) | 0.007 | ||||

| Balance tool slide motor power (W) | 1200 | ||||

| Vertical tool slide motor power (W) | 400 | 1000 | |||

| Tailstock motor power (W) | 400 | ||||

| Machine weight (kg) | ≤660 | ||||

| Total power (kVA) | 5 | ||||

| Overall dimensions (mm) | 1280×1256×1600 | 1555×1256×1600 | |||

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.

It is ideal for machining small-diameter steel parts and non-ferrous metal components.

The CNC lathe’s structure provides high inherent accuracy, but regular maintenance is essential. Proper tool-offset settings, backlash calibration and secure workpiece clamping also help ensure stable machining precision.

Tool setting is similar to that of a conventional CNC lathe, but the sliding-head design requires higher tool-setting accuracy due to its machining characteristics.