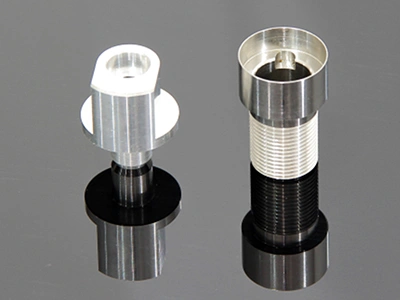

This Swiss type CNC lathe is built for high-precision machining of long, slender micro-shaft components.

AC servo control is adopted for X1, X2, Y1, Y2, Z1, Z2 axis. Four axes could be simultaneously controlled. Equipped with built-in absolute encoder, high precision linear guide and ball screw, the CNC automatic lathe ensures high positioning accuracy and rapid travel speed.

| Model | | |

| Max. bar diameter (mm) | Ø4 | Ø1 |

| Max. workpiece length (mm) | 30 | |

| Max. spindle speed (r/min) | 16000 | |

| Spindle through-hole diameter (mm) | Ø100.75/1.1 (built-in motor) | |

| Spindle center height (mm) | 1150 | 1130 |

| Spindle motor power (kW) | 0.75/1.1 (built-in motor) | |

| OD turning tools (pcs) | 4 | 5 |

| Front drilling tools (pcs) | 3 | / |

| Radial driven tools (pcs) | 2 | |

| Back machining tools (pcs) | 2 | / |

| Turning tool shank size (mm) | Ø8×100–120 | |

| Max. sub-spindle speed (r/min) | 16000 | / |

| Sub-spindle motor power (kW) | 0.75/1.1 (built-in motor) | / |

| Rapid traverse of all axes (m/min) | 20 | |

| Servo motor power (X1/Z1/Z2) (kW) | 0.4 | |

| Servo motor power (X2/Y1/Y2) (kW) | 0.5 | |

| Repeatability of all axes (mm) | 0.002 | |

| Spindle hole radial runout (mm) | 0.004 | |

| Coolant pump motor power (kW) | 0.15 | |

| Total power (kVA) | 5 | |

| Air pressure (MPa) | 0.6 | |

| Air flow rate (NL/min) | 100 | |

| Machine weight (kg) | Approx. 1000 | |

| Overall dimensions (mm) | 1875×800×1710 | |

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.

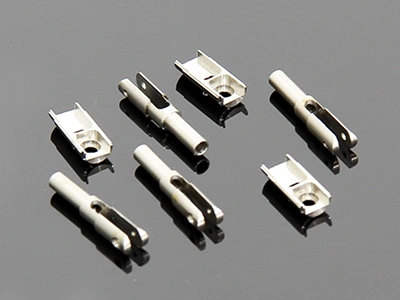

A Swiss-type CNC lathe is mainly used for machining probe-type micro components with diameters of ≤ 1 mm.

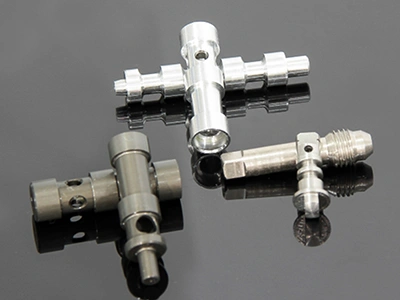

A Swiss-type CNC lathe provides high spindle speeds (up to 16,000 r/min), multi-axis control, and 0.002 mm positioning accuracy. These features support the machining of rotor journals, slots and other complex geometries while ensuring dimensional stability and surface quality. It is suitable for both small-batch and mass production of precision motor rotor components.