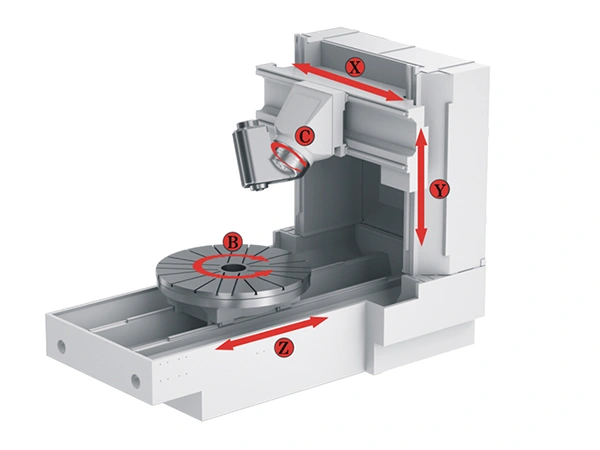

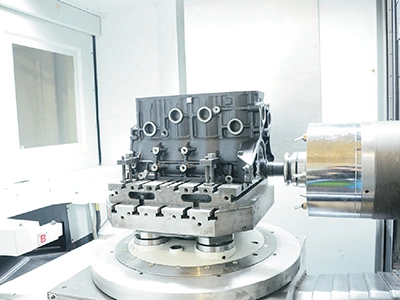

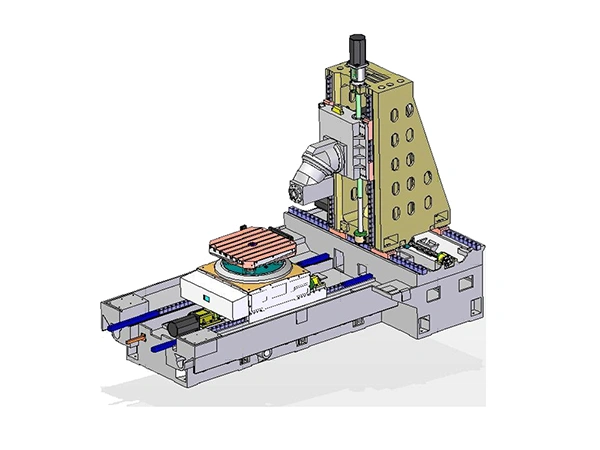

The 5-axis machining centers with a 45° tilt head use a T-shaped layout, with the column moving on the X axis, the spindle head travelling vertically on the Y axis, and the table advancing along the Z axis. Table sizes range from 650 to 1200 mm, and a vertical-table configuration is available when an upright orientation is required.

The spindle head tilts 45°, allowing vertical and horizontal machining in one setup. Continuous rotary movement can be provided through a high-precision worm-gear rotary table. When higher responsiveness and zero mechanical backlash are needed, a torque-motor direct-drive rotary table can be selected. A torque-motor direct-drive milling-and-turning table is also available for applications that require both operations.

THM63160V

THM63160V

THMD63100V

THMD63100V

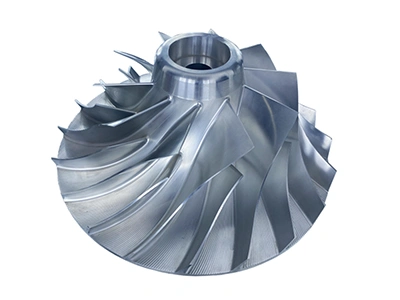

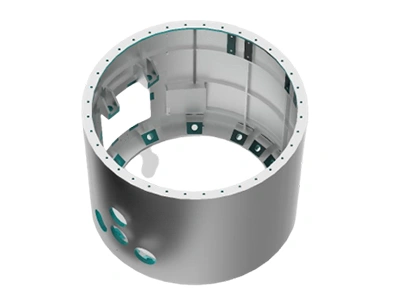

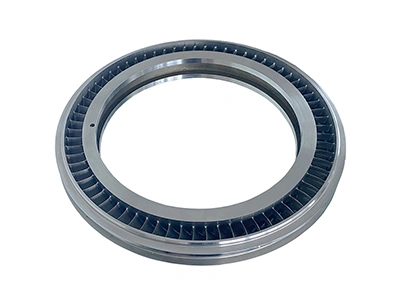

These 5-axis machining centers control movement along the X, Y, Z, B and C axes, enabling full 5-axis simultaneous machining. Spindle speeds can be configured at 7,000, 10,000, 12,000 or 18,000 r/min depending on the process requirements. Their configuration supports the machining of complex components used in aerospace, automotive, marine power systems, energy equipment and mold manufacturing.

Aerospace Industry

Aerospace Industry

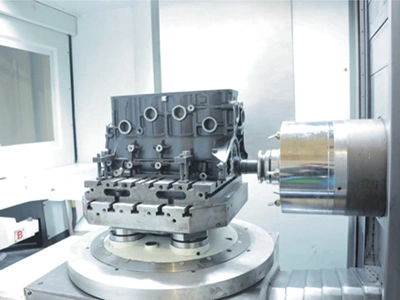

Automotive Industry

Automotive Industry

Shipbuilding Industry

Shipbuilding Industry

| Model | | | | |

| Worktable size (mm) | Ø800 /800×800 | Ø1000 /1000×1000 | Ø1250 /1250×1250 | Ø1600/Ø1800/Ø2000 |

| Max. worktable load capacity (kg) | 2000 | 2000 | 2000 | 2000 |

| X-axis travel (mm) | 1200/1400 | 1600 | 1600 | 2100 |

| Y-axis travel (mm) | 1000/1200/1400 | 1000/1200/1400 | 1000/1200/1400 | 1250/1600 |

| Z-axis travel (mm) | 1100/1400 | 1600 | 1600 | 2100 |

| B-axis swing range (°) | n×360 | n×360 | n×360 | n×360 |

| C-axis rotation range (°) | -15 to +195 | -15 to +195 | -15 to +195 | -70 to +180 |

| Spindle speed (r/min) | 20–15000 | 20–15000 | 20–15000 | 20–10000 |

| Positioning accuracy (X/Y/Z) (mm) | 0.008 | 0.008 | 0.008 | 0.008 |

| Repeatability (X/Y/Z) (mm) | 0.004 | 0.004 | 0.004 | 0.004 |

| B-axis positioning accuracy (″) | 8 | 8 | 8 | 8 |

| B-axis repeat positioning accuracy (″) | 4 | 4 | 4 | 4 |

| C-axis positioning accuracy (″) | 10 | 10 | 10 | 10 |

| C-axis repeat positioning accuracy (″) | 5 | 5 | 5 | 5 |

The spindle assembly uses a 45° tilting head that switches between vertical and horizontal machining, with the spindle mounted on this tilting axis to rotate along the C-axis for angled operations. The spindle uses a built-in motor, so the drive power goes directly into the spindle and stays steady during cutting. The bearing temperature is tracked so the spindle stays steady and the machining accuracy doesn’t drift during long cuts.

The X, Y and Z axes use servo-driven linear guide rails paired with precision ball screws. The axes can move at high speed, up to 40 m/min, while still keeping positioning steady, and the low-speed motion stays smooth without any crawling. The linear guides use a centralized lubrication system that keeps friction down and reduces wear, which helps the machine hold its accuracy over long periods of use.

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.

It’s important to check not only the 45° tilt head, but also the spindle assembly, the linear-axis guideways and ball screws, the servo motors and drive system, and the tool magazine and tool-change mechanism. These areas just need good lubrication, proper cooling and small routine checks so their movement stays smooth and the accuracy doesn’t start drifting.