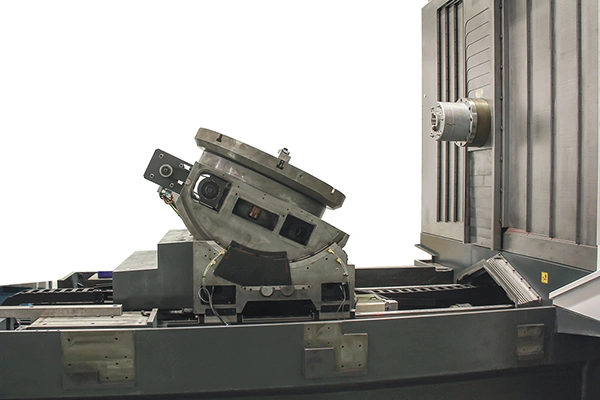

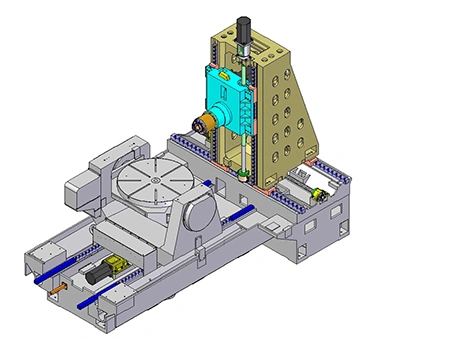

The cradle-type five-axis machining centers use a T-shaped monolithic bed to support the tilting rotary table, with worktable sizes ranging from 650 to 1200 mm. The A and B axes are driven by a worm-gear mechanism that provides high torque for low-speed and heavy-load cutting. When faster axis movement or tighter accuracy is needed, the A and B axes can be equipped with torque-motor drives. Using torque motors gives a quicker response, removes backlash and avoids wear from mechanical transmission, which helps keep accuracy steady in high-speed and high-precision work.

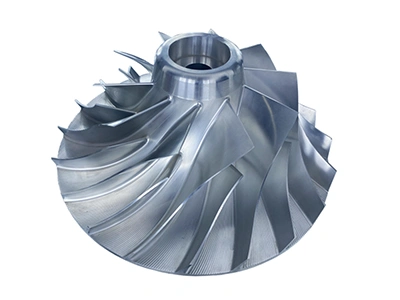

The X, Y, Z, A and B axes allow full 5-axis simultaneous machining. The spindle can be configured for either low-speed, high-torque cutting or paired with a high-speed motor spindle (8000 or 12000 r/min), depending on the material and the type of workpiece. This range of options makes the configuration suitable for aerospace components, automotive parts, marine equipment, power-generation pieces and various complex mold and tooling applications.

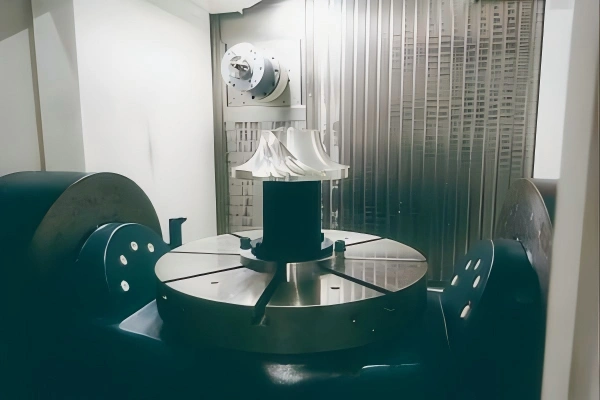

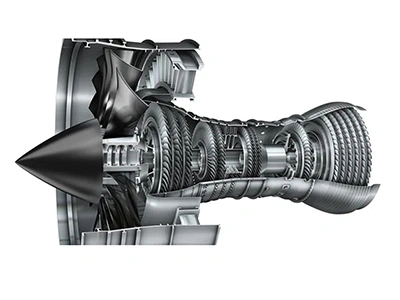

Aerospace Industry

Aerospace Industry

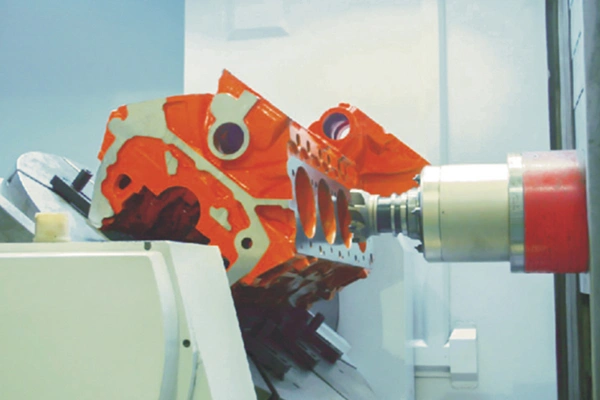

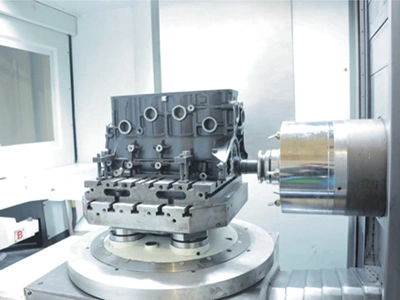

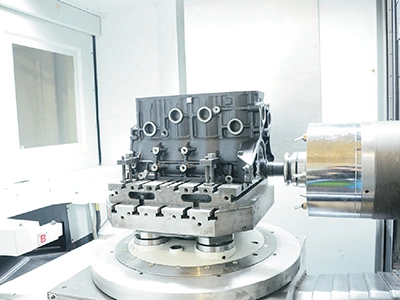

Automotive Industry

Automotive Industry

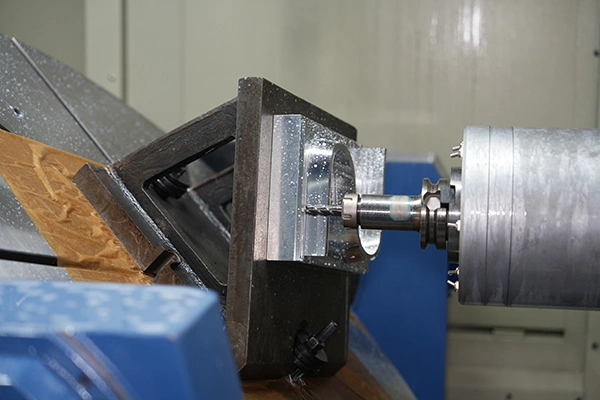

Shipbuilding Industry

Shipbuilding Industry

| Model | | | | | | |

| Worktable size (mm) | Ø500 | Ø630 | Ø800 | Ø1000 | Ø1200 | |

| Max. worktable load capacity (kg) | Tilt 100° to 45° | 300 | 300 | 700 | 800 | 800 |

| Tilt 45° to 10° | 500 | 500 | 800 | 1000 | 1000 | |

| X-axis travel (mm) | 900 | 1000 | 1300 | 1300 | 1300 | |

| Y-axis travel (mm) | 700 | 800 | 1000/1200 | 1000/1200 | 1200 | |

| Z-axis travel (mm) | 900 | 900 | 1100 | 1100 | 1100 | |

| A-axis swing range (°) | -100 to +10 | -100 to +10 | -100 to +10 | -100 to +10 | -100 to +10 | |

| B-axis rotation range (°) | n×360 | n×360 | n×360 | n×360 | n×360 | |

| Spindle speed (r/min) | 20–6000 | 20–6000 | 20–5000 | 20–5000 | 20–5000 | |

| Positioning accuracy (X/Y/Z) (mm) | 0.008 | 0.008 | 0.008 | 0.008 | 0.008 | |

| Repeatability (X/Y/Z) (mm) | 0.004 | 0.004 | 0.004 | 0.004 | 0.004 | |

| A-axis positioning accuracy (″) | 15 | 15 | 15 | 15 | 15 | |

| A-axis repeat positioning accuracy (″) | 7 | 7 | 7 | 7 | 7 | |

| B-axis positioning accuracy (″) | 8 | 8 | 8 | 8 | 8 | |

| B-axis repeat positioning accuracy (″) | 4 | 4 | 4 | 4 | 4 | |

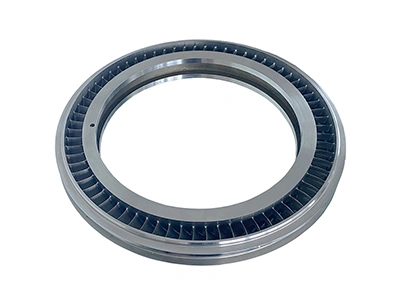

The 5-axis machining center uses a tilting rotary table that provides A- and B-axis motion. The A-axis uses a crossed-roller bearing that gives it stronger support, so it can handle heavier loads and stay steady while rotating.

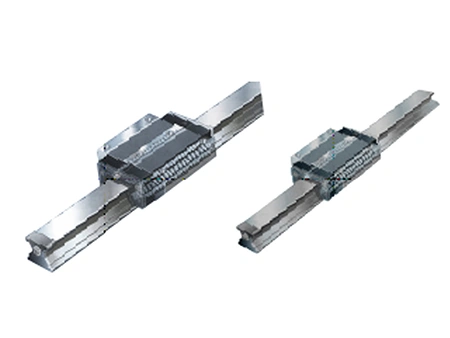

The linear guideways allow rapid movement up to 45 m/min while keeping positioning smooth and stable, even at low speeds. A centralized lubrication system minimizes guideway wear and helps maintain long-term accuracy.

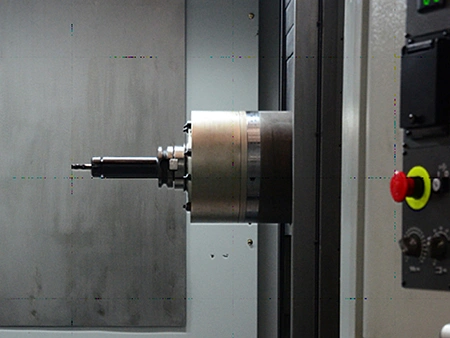

The spindle is supported by high-precision angular-contact bearings at the front and rear, which keeps its rotation stable even during heavy cuts. The bearings use long-life grease lubrication, so they don’t need routine servicing. The spindle is cooled by an external circulation system that carries heat away as it forms. By keeping the temperature stable, the spindle works more smoothly and the machining accuracy stays reliable even when the job runs for a long time.

Contact us today and our experts will help you evaluate your machining requirements and recommend the most suitable CNC machine and configuration.

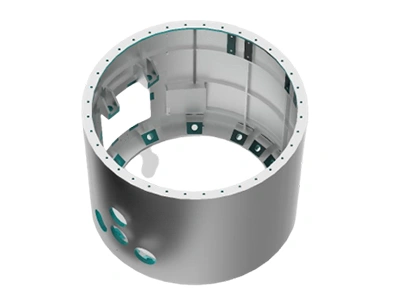

A cradle-type 5-axis machining center moves the workpiece through the tilting and rotation of the rotary table, which gives better stability when working with large or heavy components. The motion remains steady, so surface accuracy stays consistent even during long cuts. The only thing to keep in mind is that the loading area can feel a bit tighter because the table needs room to tilt.

A tilt-head design moves the spindle instead. This makes it easier to reach deep pockets or narrow sections and works better for smaller or lighter parts. The trade-off is that the spindle overhang is longer, so extremely high-speed cuts can be a little less stable compared with a cradle table.

The bearings in the rotary axes need regular lubrication checks, and grease or oil should be replenished when required. The encoders and scale units need to stay firmly in place and give clean signals, because even a small amount of looseness can affect how accurately the rotary axes position themselves. It also helps to check the rotary axes from time to time to make sure the accuracy hasn’t started drifting. If any slight shift or irregular movement appears during inspection, it's necessary to make corrections early to keep the machining accuracy stable.